And here is a picture of what I want the dial side to look like.

So the first thing I worked on this week was making the third and escape wheel bridges. These bridges were a little bit more difficult than the big one because I needed to put the locating pins and screw hole in first so it they would stay in place for the milling.

Here's the escape wheel bridge with the pins in and screwed to the mainplate.

Just milling part of the bridge and the outline of the rest on the top

Here it is with the two sides milled and the rest is just an outline on the top.

That's why I made it thicker than the final dimensions so I could mill the shape on top to aid in the filing.

And after much filing here are all the bridges on. Final dimensions will come later but for now I think it is a good start. I still probably have to make a new balance bridge but I'll worry about that later...

Next I had to center each hole on the jewels on the mainplate. Then I milled out the holes to 0.20mm smaller than the final dimension. These holes are just so I had something to center on to mill out the underside of each bridge. These cut outs are to make room for the actual wheels.

Here are the bridges with the underside cut out to make space for the wheels. It took me about 4-5 hours to do all the re-centering and milling.

Here are all the pieces from the underside. You can see the locating pins sticking out. Two for each bridge.

Here are all the pieces from the underside. You can see the locating pins sticking out. Two for each bridge.I actually kinda milled out a bit too much around the center jewel, but I don't think it will be a problem. My mainplate will get a few hundredths thinner when I have to retouch it anyways.

The other thing I was doing this week was making the moon phase wheel. If you have talked with me about watches a lot you will notice I really like the moon phase complication. I just think it looks nice. Not the most complicated or useful thing but whatever, I like it! I could've just used a wheel from another watch somewhere but I thought it would cool to try and make one of my own and decorate it the way I see fit.

There are 59 teeth on the wheel. This is because the length of a moon phase is 29.53 days. Therefore to make the system more accurate we put 59 teeth on the wheel and make it jump 1 tooth per day. That is also why there are 2 moons on the disc.

Now to say the process of making this wheel was not easy/fun is a large understatement. Just to cut the teeth took about 8 hours. The reason for this is I had to cut each tooth in steps. Each one is 0.34mm deep and you can't just cut all the way in at once. I was cutting about 0.03-0.04mm per pass so that is about 9-10 passes per tooth. Times that by 59 and you get about 550-600 times back and forth. And you can only cut in one direction so I would have to go in, cut across, lift up, return to the start, and go in deeper.

On top of this there is a spacer wheel which divides the turning of the piece into 59 divisions. That's all good but you have to make sure you don't turn it 1 too many or too less holes or the whole wheel will be ruined. It was a lot of concentration for a full day. But it felt great when I was done!

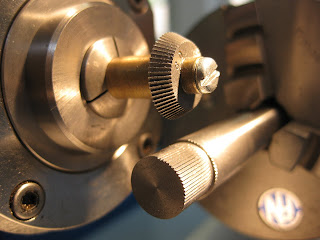

All of this wouldn't be possible without my buddy Schaublin!

And here are the wheels I got from all that work. The one is a little blue because I heated it up a bit too much when I was ungluing it from the brass. But it won't make a difference once I harden and temper it.

The other thing with the holes is the container I made to hold the wheel when I have to harden the steel. I needed to make something to sandwich the wheel in there so it won't warp when it gets really hot. The holes are allow oil in to quench the steel and cool it down. Hopefully it all works out!

One other thing I did this week was mill out the location for the new hour/minute positions and the intermediate wheel. But everything looks like it will work out so far. I probably have to make another wheel that will only rotates once a day for the moon phase wheel, but that's a later project. I also need to figure out the power reserve system but I have a plan for that so I just have to figure out the details.

This week I will be enlarging the holes in the bridges for the jewels. Once I do this I can actually get the watch running again! It will be cool to have it running with the new bridges.

Here is one last pic this week. It kinda shows on the mainplate all the holes I might be have to plug. There are a lot of useless holes on the mainplate and I don't want any of them to be visible from the bridge side. Not very complicated to fill, just a lot of them!!

Bye for now!

Wow, looks like a great project. I always knew the Swiss schools got into more cool things than the American ones.

ReplyDeleteHi Aaron!

ReplyDeleteI'm having a bench test at WOSTEP school in Neuchatel next week. Could you please advise me on what does it consist from? I would love to prepare for it but haven't really got any info about it.

Thanks in advance:)

Nik

Excellent, detailed blog. I'm following it with interest. Best of luck with your course.

ReplyDeleteReally interesting series and thanks a bunch for sharing it!

ReplyDeleteNik,

ReplyDeleteAbout the bench test. It's not really something you can prepare for actually. For my test I had to file a brass cylinder, bend some hairsprings into shapes, some 3d drawing, some pretty basic math, and take apart a watch and put it back together. So really most of the stuff you probably wouldn't be able to practice at home anyways.

I actually didn't need the whole 2 days for my test, I was finished before lunch the second day.

What day are you coming, and where are you from?

Aaron,

ReplyDeleteThanks for your help:) I'm coming on Tuesday from London, where I live and work. Originally I'm from Estonia, though. How hard is the test? Are there many people failing?

I don't really think it is a matter of passing or failing. It's more whether or not you can do the stuff they ask you to do. I didn't find it really that difficult, but I had taken a watch apart once or twice before so that part wasn't too difficult.

ReplyDeleteFunny thing though, when I was finished the test and after I went home I literally had no clue whether I did good or bad. They didn't tell me anything at the school. They said they would let me know in 2-3 months. But actually it was only 2 weeks before they sent me an acceptance letter.

I did my test by myself, but I think some of the other guys did the test at the same time as a few others.

Thanks Aaron! I hope I'll pass the test, feeling a bit nervous though:)

ReplyDelete